RHINOGROOVE...Strength & Stability

C&B Supply Is Proud To Be A New Distributor For....

Nine9 News Release

New Grades Available

Nine9 NC5074 Helica Coating

Nine9 NC5072 TiAlN Coating

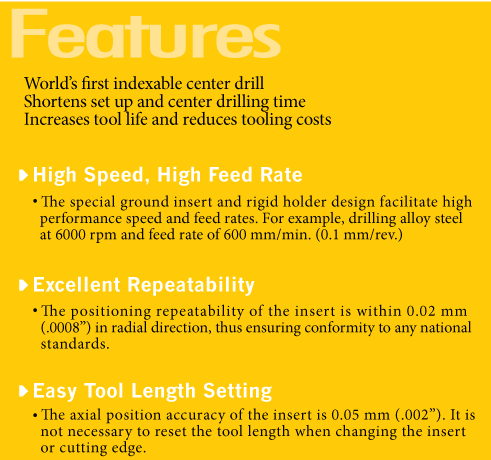

New Grade Available. Patented. The developer of the first indexable center drill in the world. Offering and indexable insert system for the 1st time, Nine9's "i-Center" design improves your process performance.

New Helica Grade replaces the NC2033 for the following items:

NC 5074:

P40 grade, Helica coating, design for small diameter center drill (IC08 inserts).

Extended Tool Life

- coolant can be supplied through the center of the holder to increase performance and extend tool life.

- Insert geometry, grades and coating process are specifically engineered for centering applications.

Special forms are possible

AICrN based

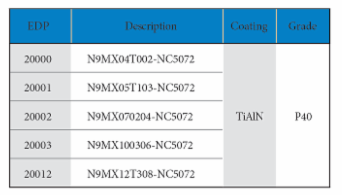

New NC5072 TiAIN grade replaces the (NC5074) for the following items:

NC5072:

P40 grade, TiAIN coating

General purpose, suitable for almost all kinds of steel, stainless steel and Titanium.

Why Helix Angles Are So Important For Machining Aluminum

Solving Challenging Workholding Problems

Introducing IN THE LOUPE

Helical's technical content can now be found on In The Loupe, their new blog is shared with their sister company Harvey Tool Company. Access helpful resources, technical tips, and be sure to check in often to stay in The Loupe! Click here to subscribe and never miss their latest blog post.

At C&B Supply we are especially excited about the information found on In The Loupe Troubleshooting Tips. Browse topics such as 'Reducing Tool Runout', '7 Common Dovetail Mistakes', 'Spot Drilling' and so much more. Check it out now and as always contact C&B Supply for all your Helical and Harvey Tool needs.

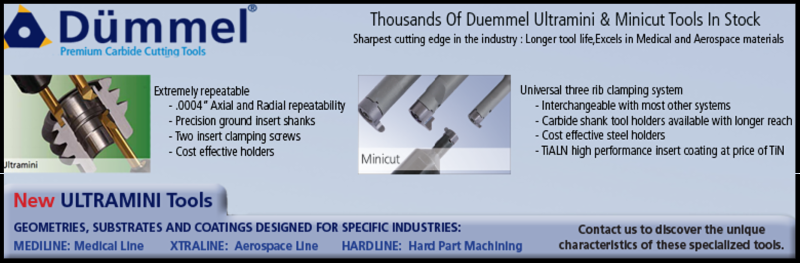

2017/2018 Duemmel Product Catalog Now Available

- Over 700 New Items Added

- 24 New Or Expanded Product Types

- Hundreds Of New Inch Items to Better Serve the USA Market

Summary of Product Expansion

ULTRAMINI

Benefits of Using Ultramini

- Highly repeatable holder systems.

- Sharpest cutting edge in the industry.

- Thousands of tools require only 2 holders.

- Outperforms other major competitors.

- Interchangeable with a major competitor.

Holders:

Type 645.PT, Type 676.PT, Type 687.PT

- PT style holders deliver coolant parallel to the insert shank.

Inserts:

Mediline Type M050

- Specifically designed foe 316 SS and titanium materials.

- Coolant delivered thru the tool.

- Reduced t max for higher stability.

- Corner radius provides longer tool life and better surface finishes.

Type UM600H - High Performance

- Standard coolant connection

- Manual clamping without additional wrench

- Continuous repeatability - highly precise

- Simplest orientation

- Ideal where space is tight

Xtraline Type X050

- Specifically designed for Nickel and Chrome base alloys.

- Coolant delivered thru the tool.

- Reduced t max. for higher stability.

- Various corner radii provides for longer tool life and better surface finishes.

- Chip breaker reduces cutting forces and provides for higher cutting feed.

Hardline Type 050

- More economical than CBN.

- Machine up to HRC66.

- Reduce scrap.

- Perfect for thin wall material

Type 004M, Type 006M, Type 007, Type 007M

- Grooving inserts with corner radii

- Inch widths added

NPT Partial Profile Threading

- 18 and 27 TPI

MINICUT

Benefits Of Using Minicut

- Interchangeable with the industry standard tri-groove mounting system.

- AL41F outperforms competitors grades with NO up-charge for our TiALN coating.

- Sharpest cutting edge in the industry equal increased tool life; better chip formation and surface finish.

Holders:

Type 614.A & 618.A

- Prefered holder style for face grooving

Type 14SQ, Type 14SQ.A (square)

- Metric shank standard

- Inch sizes available upon request

Inserts:

Internal Grooving / Profiling 08, 11, 14, 16 Series

- Expanded inch offering

- Expanded offering with radii

Boring And Copying

- Expanded 08, 09, 11, 14, 16 program

NPT Partial Profile Threading

- 14, 18, 27 TPI